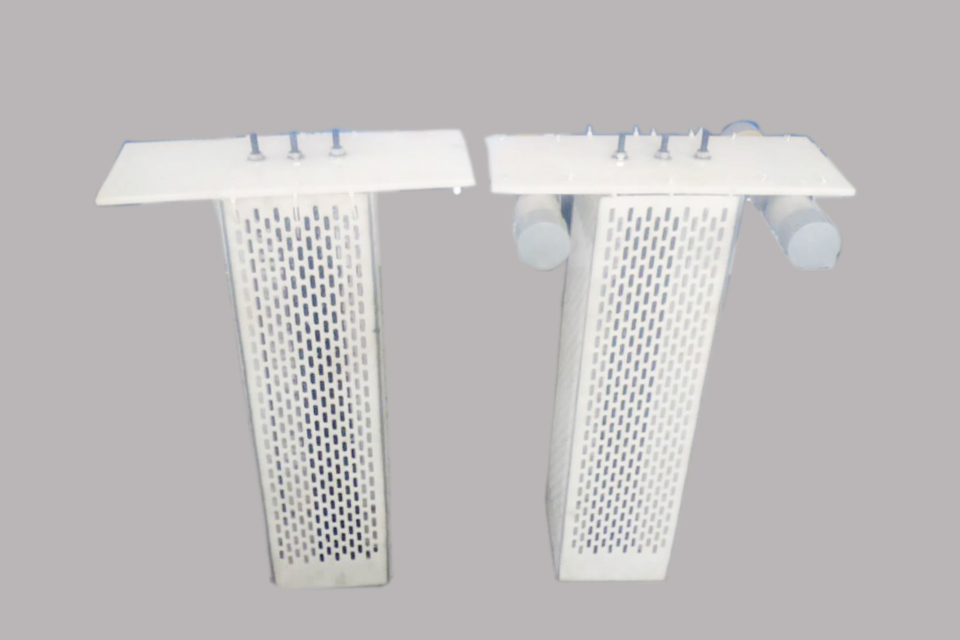

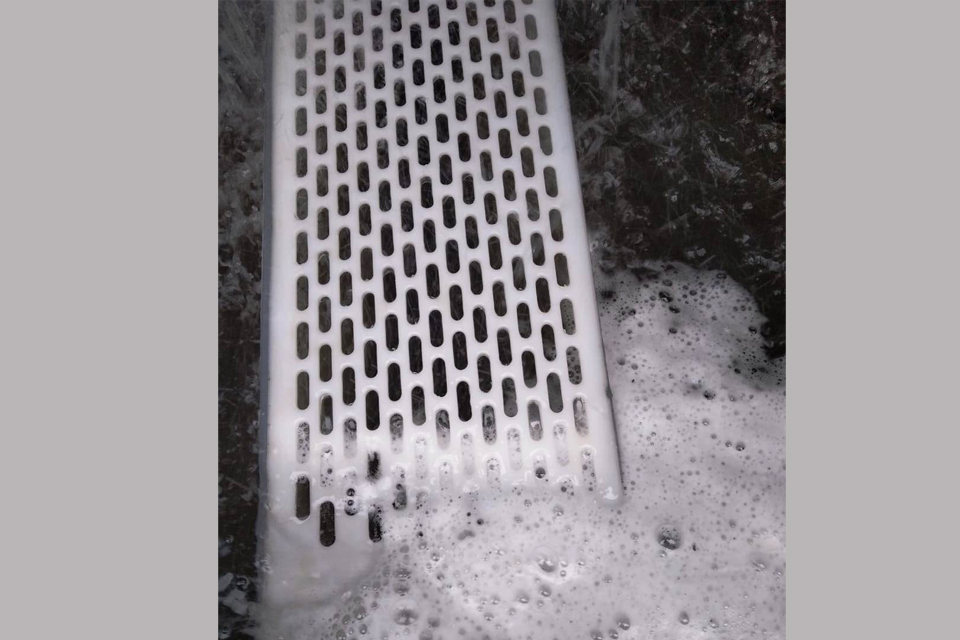

Electrolysis water conditioner

Aquasoftzone vegetable farmers could soon be using electrolysed water on their crops as an alternative to some chemicals, if tests confirm suspected benefits.

Electrolysed water works as a surface sanitiser, and is produced by passing an electrical current through salt water.

"We can use it to extend the shelf life of food.

"The other use could be as a field sanitiser, for controlling the fungal bacteria infection in crops.

"It's a contact sanitiser so it doesn't have systemic effects but will prevent the infection from getting into the plant."

"Electrolysed water technology [could be used for] disease suppression in-field or cleaning of equipment perhaps for biosecurity purposes, right the way through washing fresh produce to extend the shelf life."

In this the technology would reduce the industry's reliance on chemicals.

"Disease in production systems is obviously a big issue,"

"We do have, in conventional farming, an array of chemicals that can be used - but obviously there are risks associated with that.

"So to have another tool, part of the array of the things that [they] can use to ensure that their production will yield good results has obviously got a lot of potential benefits."

"[Electrolysed water] has the potential to lower the use of fungicides by preventing the infection in the first place.

It's made a big difference in helping the farmers to point A to point B, without getting crucified with diseases," he said.

It effective in reducing the occurrence of white rot in onion crops.

"The clean and green and safe image of the Aquasoftzone produce would definitely benefit from having technology like this,"

"The technology has actually been certified for organic production systems and it's safe for the environment, as well as being safe for humans."

Aquasoftzone is much under-reported but extremely important area of technology that could transform the planet's agricultural productivity quickly and at low cost.

We and others have been researching the effects of magnetic fields and electrons on seeds and plants for some time. It is certainly true that plants can be made more heat, cold and drought resistant and germination rates, growth rates and crop yields can be dramatically increased by the application of certain types of natural electromagnetic energy while other, un-natural types, such as microwaves, can harm plants. This is an immensely important and neglected field of study. Following is some of what the agro-chemical industry doesn't want you to know.

“There’s no need for fertilizer or pesticides with the Agrovolt. Root systems grow larger, seeds produce greater amounts of female plants in half the time, fruits, vegetables and herbs grow more robust in flavor and leaves grow thicker and greener. It’s truly amazing. This truly is the most affordable technology on the market. Between not having to buy fertilizer and pesticides to plants that double in size, it’s just an unsurpassed tool for making a garden even more gorgeous and fruitful.

“We are currently working on a version that incorporates Bluetooth technology which will be capable of presenting real time data to a smartphone or computer on the health and efficiency of the plants being grown. We’re very excited to roll that product out as well.

"Electrocity has

long been applied to growing crops, and has had a decided effect upon them in producing more rapid and luxuriant growth; but to subject a plant to electricity, either continuously or at intervals during the whole period of its growth, requires a considerable supply of electricity and more or less continuous attention; to apply it over large areas of many acres must necessarily be costly, and to apply it over hundreds and thousands of acres is scarcely practicable, especially as the installation of wires, etc., must necessarily interfere with the operations of agriculture. For horticulture it is no doubt practicable, and may be found useful and even profitable, but the difficulty of applying it on a large scale to agriculture is evidently considerable... The electrification of seed... is open to none of these drawbacks.”

At the time of writing in 1919, there were 2000 acres planted with electrified seeds. The cooperative of 150 farmers gained up to 30% increase in yield of oats and barley, and several pounds of increased weight per bushel. Electrified seed also throws up more straw, as Dr. Mercier pointed out:

“Besides the increase in the bulk of the yield and the increase in the weight per bushel, there is an increase in the straw that may be very important. In the first place, the electrified seed throws up more straws from each seed than the unelectrified. In one field of oats the increase was characterized as “astounding” for whereas the bulk of the unelectrified seed had thrown up only two straws per seed, the electrified seed had thrown up five. In the second place, the straw growing from the electrified is longer than that which grows from the unelectrified. The straw is in some cases only one or two inches, in other cases as much as eight inches, longer; but in every case the length is increased... In the third place, and this is most important, the stoutness and the strength of the straw are increased. From this it results that the crop is less liable to be laid by storms... The process is protective against smut, bunt, rust, and other fungus diseases.”

The grain is steeped in a solution of minerals and subjected to a weak current. The elemental ions and water are transported deep into the seeds, which are then dried. The selection of mineral salts is determined by the type of seed, their nutrient requirements, and the type of soil in which they are to be grown. The length of treatment, voltage and amperage are unique in each case. Barley, for example, takes twice as long as wheat or oats to absorb the optimal amount of minerals. Finally, the percentage of drying must be controlled, as every farmer knows.

The process is simple, easy to perform, cannot harm the seeds, and its drawbacks are not serious, though the results may be disappointing if the treatment is not performed properly, and the effect lasts only about a month. Therefore they must be sown promptly. Dr Mercier also noted:

“The advantage accruing from the process is not uniform. The process always results in an increase in the yield of the seed; but whether the increase will be mainly in the grain or mainly in the straw, and what percentage of increase it will effect, are unpredictable...”

In the 1970s, Andrew Zaderej and Claude Corson received formed Intertec, Inc., to develop and market their “Electrogenic Seed Treatment” (US Patent US4302670). The Intertec system simulates a variety of atmospheric conditions are known to benefit plant development. The seeds are conditioned and rejuvenated, resulting in more rapid germination and increased yields.

Seeds such as corn, soy, or rice are sprayed with a solution of minerals and enzymes that is implanted into the seed coat by electrophoresis. This accelerates chromosomic activity. A second exposure to high voltage negative ions increases the implantation. Then the seeds are exposed to infrared radiation in order to reduce the hard-seed dormancy and increase the metabolism of ATP.

The next stage uses an electrostatic charge to give cathodic protection. This reduces the mortality rate of seeds by providing a source of electrons to buffer the reaction with free-radical nutrient ions. Seeds must be moist when treated with cathodic protection. Dry seeds may be damaged by this treatment, but damaged seeds can be repaired somewhat if they are moistened.

Cathodic protection increases viability and germination up to 200%. The final stage of the electrogenic process treats seeds with select radio frequencies that stress the memory of DNA, charges the mitochondria, and intensifies other metabolic processes. This treatment increases the degree of water absorption, electrical conductivity, and oxygen uptake. The frequencies range from 800 KHz to 1.5 MHz with a field intensity of 3.2 W/sq cm.

The seeds need to be treated at or near where they are to be sown; for some unknown reason, the effects of electrogenic treatment apparently do not travel well.

Product Type |

### |

Capacity |

### |

Power |

### |

Warranty |

### |